How to Build a Chicken Tractor: Easy Step-by-Step Guide

How to Build a Chicken Tractor: Easy Step-by-Step Guide

A chicken tractor is one of the most practical tools you can build for a small homestead or backyard. At its core, it’s a movable, floorless pen designed to give your flock safe, daily access to fresh pasture. Think of it as a mobile coop that protects your chickens from predators while letting them do what they do best: forage for food, fertilize your land, and just be healthier birds.

What Is a Chicken Tractor and Why You Need One

A chicken tractor isn't just a coop—it's a cornerstone of regenerative agriculture, whether you're working a small backyard or a larger pasture. It combines housing, protection, and feeding into one mobile unit, creating a system that’s better for your chickens, your land, and the food you produce. It completely sidesteps the need for a static, smelly coop that demands constant, back-breaking cleanouts.

The whole idea is to stop bringing food to the chickens and start bringing the chickens to the food. That simple shift changes everything.

The Core Benefits for Your Flock and Land

Moving your flock to fresh ground every day or two offers huge advantages that a fixed coop just can't touch. These benefits build on each other, creating a healthier, more productive little ecosystem right in your own yard.

Improved Flock Health: When chickens get a varied diet of grasses, seeds, and insects, their immune systems get a serious boost. Being on clean ground all the time also slashes their exposure to the parasites and diseases that build up in manure.

Superior Egg and Meat Quality: That diverse, nutrient-rich diet from foraging goes straight into the food they produce. You'll see it in the deep, orange yolks of their eggs and taste it in the final product. If you're raising chickens for eggs, this is a game-changer.

Natural Pest and Weed Control: Chickens are nature's best foragers. They’ll happily gobble up pests like ticks, grasshoppers, and slugs, not to mention weed seeds. It’s natural, chemical-free maintenance for your lawn or garden.

Soil Fertilization: As you move the tractor, your chickens leave behind a perfect layer of nitrogen-rich manure. This process systematically builds soil fertility across your property, turning a waste product into a black-gold resource.

The chicken tractor concept is all about smart, sustainable poultry management. These mobile pens are designed to give chickens fresh forage and healthy living conditions, with a single tractor typically housing anywhere from 25 to 80 birds, depending on its size. You can learn more about pastured poultry management from the experts at PennState Extension.

Ultimately, using a chicken tractor lets you work with your chickens' natural behaviors—scratching, foraging, and exploring—instead of fighting against them. It’s simply a smarter, more sustainable way to raise a happy, healthy flock.

Choosing the Right Chicken Tractor Design

Before you even think about picking up a hammer, let's talk design. This is the single most important decision you'll make, and getting it right from the start will save you a world of frustration. The perfect chicken tractor for a flat, manicured lawn will be a disaster on a bumpy pasture. A good design is your foundation.

It all starts with matching the tractor to your actual needs. Think about your flock size, the kind of ground you'll be moving it across, and your local weather. These factors will naturally guide you toward the right style—whether that’s a nimble A-frame, a versatile hoop coop, or something a bit more heavy-duty.

Popular Chicken Tractor Styles

Out in the real world, you'll see a few designs pop up again and again. Each has its own strengths, and knowing the difference will help you choose with confidence before you start buying materials.

The A-Frame Tractor: This is the classic for a reason, and often the go-to for beginners. That triangular shape is naturally strong, shedding rain and snow with ease. A-frames tend to be lightweight, making them easy for one person to move every day. They're a fantastic choice for smaller flocks of 4-8 birds on fairly even ground.

The Hoop Coop: Made by bending PVC pipes or cattle panels into an arch, hoop coops give you a lot of interior space for their weight. A heavy-duty tarp stretched over the top provides great shelter from sun and rain. Their rounded shape handles wind well, but you’ll definitely need to anchor them securely.

The Salatin-Style Tractor: Named after the legendary farmer Joel Salatin, these are big, low-slung rectangular pens. They're built for raising larger batches of meat birds on pasture. Because they're heavy and durable, you'll need a special dolly to move them. This is the workhorse for serious homesteaders focused on pasture rotation.

The choice really boils down to mobility versus capacity. An A-frame is quick and agile, while a Salatin-style tractor is a serious pasture management tool.

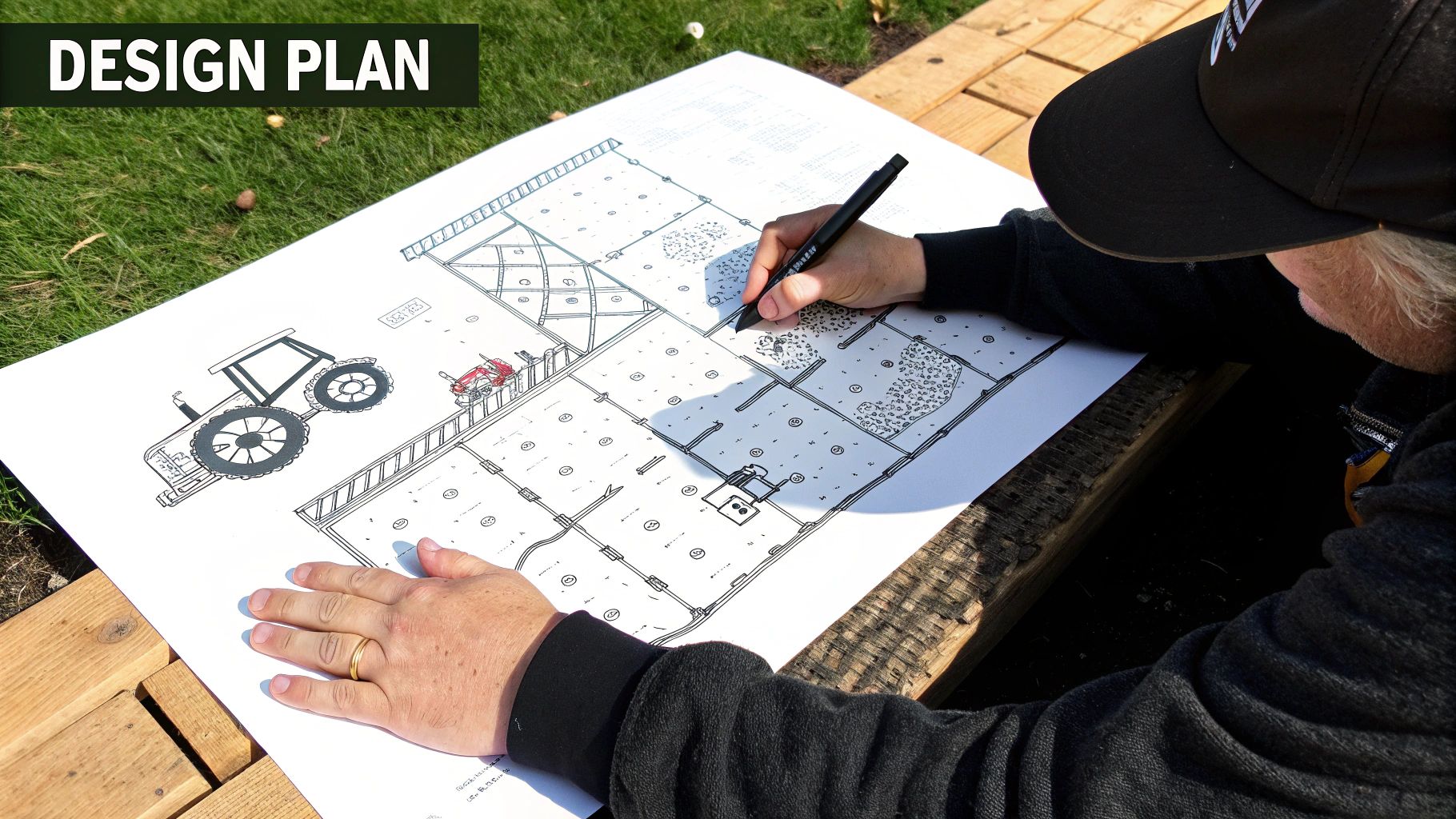

Sketching a Plan with Key Features

Once you've settled on a style, it's time to map out the non-negotiable interior features. These are the little details that keep your flock safe, comfortable, and productive. Don't gloss over them.

First, you absolutely need roosting bars. Chickens have a deep-seated instinct to sleep elevated off the ground. A crucial tip from experience: always place the roosts higher than the nesting boxes. If you don't, you'll be cleaning chicken poop out of the nests every single day.

Next up are easy-access nesting boxes. An external door for egg collection isn't a luxury; it's a necessity. It lets you grab fresh eggs without stepping inside, scattering the flock, or letting a bird dart out. If you're looking for more layout ideas, our complete guide on building a chicken coop for beginners dives deeper into these specifics.

Finally, plan your doors. You need a small one for the chickens and a larger, human-sized door for you. That big door is essential for cleaning, refilling food and water, or getting to a bird that needs help.

Durability and Predator-Proofing

A chicken tractor is your flock's fortress on wheels, so it has to be tough. Your design needs to be sturdy enough to handle daily moves and whatever weather your region throws at it, all while keeping predators out.

Over the years, many homesteaders have learned that a successful design is a careful balance of durability, predator defense, and mobility. Early prototypes might be simple boxes, but trial and error quickly shows the need for tougher construction to fend off predators and handle rough ground, without being too heavy to move. You can find more real-world insights about these design evolutions on WestonAPrice.org.

The most critical takeaway is that your tractor is only as strong as its weakest point. A clever raccoon can defeat a simple latch, and a determined coyote can tear through flimsy chicken wire.

To build a truly secure tractor, you have to get these details right:

Use the Right Mesh: Standard chicken wire is for keeping chickens in, not predators out. You must use 1/2-inch hardware cloth on every opening, secured with heavy-duty staples or screws and washers.

Secure All Access Points: Every single door and lid needs a two-step, predator-proof latch. A simple hook-and-eye just won't cut it.

Eliminate Gaps: Make sure the frame sits flush with the ground when it's parked for the night. Predators are experts at exploiting any gap they can squeeze or dig under.

The last piece of the puzzle is proper ventilation. Good airflow is non-negotiable for preventing respiratory problems and moisture buildup, especially in humid climates or during winter. Design vents near the roofline to let warm, moist air escape, keeping your flock healthy all year.

Your Complete Tools and Materials Checklist

With a solid design in your head, it’s time to shift gears to one of the most satisfying parts of any build: gathering the supplies. Trust me on this one—having every last board, screw, and hinge on hand before you make the first cut is the secret to a smooth project. It’s the difference between a productive weekend and a dozen frustrating trips to the hardware store.

Think of it like getting all your ingredients prepped before you start cooking. We’ll break down exactly what you need, from the workhorse power tools to the specific lumber and fasteners that will keep your tractor standing strong for years.

The Essential Toolkit

You don’t need a professional workshop to build a great chicken tractor, but a few key power tools will make the job tremendously easier and the results far more professional. Most of these are staples in any DIYer's garage.

Power Drill and Driver: This will be your best friend for driving hundreds of screws and drilling pilot holes. A cordless model is a must for freedom of movement.

Circular Saw or Miter Saw: Absolutely essential for making straight, accurate cuts. A miter saw is a dream for perfect angles, but a good circular saw is more than capable.

Tape Measure and Carpenter's Square: Precision is everything. The old saying "measure twice, cut once" exists for a reason, and a square guarantees your corners are actually square.

Heavy-Duty Staple Gun: You’ll be using this to attach your hardware cloth. Don't cheap out here; a flimsy staple gun will make you want to pull your hair out.

Pliers and Wire Cutters: A must-have for wrestling with hardware cloth. You'll need them for cutting, bending, and shaping the mesh.

Having these basics ready means you can tackle just about any chicken tractor plan with confidence.

Choosing Your Lumber and Sheeting

The wood and paneling you pick directly impacts your tractor's weight, durability, and bottom-line cost. It’s a bit of a balancing act. For the frame base—the parts that will be in constant contact with damp ground—it’s smart to use pressure-treated lumber for its rot resistance.

But for any interior areas where your flock will live, roost, and peck, stick with untreated pine or fir. You never want your chickens exposed to the chemicals in treated wood. When it comes to siding and roofing, you've got options like corrugated metal or exterior-grade plywood, each with its own pros and cons for weight and weather protection.

One of the biggest lessons you learn on a project like this is to spend money where it really counts. Using flimsy chicken wire instead of 1/2" hardware cloth or building the entire frame from untreated pine is a recipe for disaster. You'll end up with predator break-ins or a rotted structure in just a season or two, costing you far more in the long run.

To help you weigh your options, here’s a look at some common material choices.

Chicken Tractor Material Comparison

This table breaks down some of the most common materials for your tractor's main components. Think about your local climate, your budget, and how often you'll be moving the tractor when making your choices.

Ultimately, the best choice is often a mix-and-match approach—a durable pressure-treated base with a lighter pine upper frame, for instance.

Hardware and Fasteners

The little things are the big things. Using the right screws and hardware is what will keep your chicken tractor from rattling apart after a few months of being dragged across the pasture.

You'll want a healthy supply of exterior-grade deck screws, probably in a couple of lengths like 1 5/8-inch and 3-inch. These are coated to resist rust and corrosion. Also, be sure to grab heavy-duty staples for your staple gun. If you're going with a metal roof, a box of roofing screws with built-in neoprene washers is a must—they create a waterproof seal that prevents leaks.

Finally, don't walk out of the store without hinges and predator-proof latches for every door and nesting box lid. A simple hook-and-eye latch isn't enough to stop a determined raccoon.

Building Your Chicken Tractor Frame to Finish

Alright, you've got your materials stacked and your plans laid out. This is where the sawdust starts to fly and a pile of lumber becomes a real, working home for your flock. We’re going to walk through this build from the ground up—from the base frame to the last piece of hardware—focusing on the little details that make a tractor strong, straight, and easy to move.

It’s all about building with intention. Every single cut and screw matters for the tractor's final strength and usefulness. If you take the time to get these early steps right, especially squaring up that base frame, you’ll be rewarded with a coop that lasts for years.

Constructing a Square and Sturdy Base

The base frame is the absolute backbone of your chicken tractor. It takes all the weight of the structure and has to stand up to being dragged across the pasture every single day. A flimsy base guarantees a rickety tractor that will twist and fall apart under pressure.

Start by cutting your base pieces from pressure-treated lumber. Its rot resistance is essential for anything that lives on the ground. Once your boards are cut, lay them out on a dead-flat surface—a garage floor or driveway is perfect for this. It’s the only way to be sure your frame will stay square as you join it together.

Before you drive a single screw, use a carpenter's square to check that every corner is a perfect 90-degree angle. This is non-negotiable. If your frame isn’t square, every other measurement you make from that point on will be off, creating a mess of problems down the line.

A pro tip that has saved me countless headaches: measure the frame diagonally from corner to corner. If those two measurements are identical, your frame is perfectly square. This is a 30-second check that can save you hours of frustration.

Once you know it’s square, start joining the corners. Always pre-drill your screw holes, especially when you're working near the end of a board, to keep the wood from splitting. I use 3-inch exterior-grade deck screws for their holding power and rust resistance.

Erecting the Walls and Roof Rafters

With a solid base frame built, it's time to start building up. This is the moment your chicken tractor really starts to take shape, and it’s a great feeling. The walls will support your siding and roosts, and the rafters will create the skeleton for the roof.

First, cut your wall studs to length. If you're building an A-frame, you'll be making angled cuts, so a miter saw will make your life a lot easier here. Attach the studs to the base frame, using your square to make sure each one is perfectly perpendicular.

After the wall framing is up, you’ll install the roof rafters. These pieces tie the tops of the walls together and set the pitch of your roof. Getting the angles right is what ensures your roofing panels will fit snugly and shed rain properly.

To keep everything lined up during this phase:

Work methodically: Attach one stud at a time, and use a level to check for plumb (that it's perfectly vertical) as you go.

Use temporary braces: A few pieces of scrap wood can be tacked on to brace the walls and stop them from wiggling while you work.

Consistency is key: Double-check that all your identical parts, like studs or rafters, are cut to the exact same length. Even a quarter-inch mistake here can cause big headaches later.

This systematic approach saves you from the painful job of going back to fix misalignments.

Attaching Siding and Stretching Hardware Cloth

The skeleton of your tractor is built; now it’s time to give it some skin. Adding the siding and hardware cloth is what encloses the space, provides shelter, and—most importantly—creates the first line of defense against predators.

Start with the siding on the sheltered part of the coop, where your nesting boxes and roosts will be. Whether you’re using plywood, T1-11, or corrugated metal, measure carefully and cut precisely to fit the frame. Fasten the siding with shorter, 1 5/8-inch exterior screws.

Next up is the most critical step for security: installing the hardware cloth. Do not even think about using chicken wire; it’s flimsy and predators can rip right through it. For all open-air sections, you need to use 1/2-inch hardware cloth.

Roll out the hardware cloth and use a pair of heavy-duty wire cutters to trim it to size. The secret to a tight, secure fit is to start stapling at one corner and pull the mesh taut as you work your way across the opening. Use a heavy-duty staple gun and put a staple every few inches. For ultimate protection, I always reinforce the staples by driving screws with washers over the mesh along the frame. This makes it almost impossible for a predator to pry the mesh away from the wood.

Essential Finishing Touches and Maintenance

The frame is up and your chicken tractor is starting to look like the real deal. But don't put your tools away just yet. These next few steps are what separate a decent build from a great one—turning a simple wooden box into a secure, long-lasting piece of farm equipment.

Taking the time to get these finishing touches right will save you a ton of headaches later. We're talking about adding wheels that make daily moves a breeze instead of a back-breaking chore, weatherproofing the wood so it doesn't rot after one wet winter, and—most importantly—installing latches that a clever raccoon can't pop open at 2 a.m.

Making Your Tractor Mobile and Secure

A chicken tractor is only useful if you can actually move it. This is where wheels or skids come in, and your choice really depends on your specific design and the lay of your land. For most A-frame or other mid-sized tractors, a set of heavy-duty wheels on one end is the way to go. You just lift the other end like a wheelbarrow and roll it to a fresh patch of grass. It's a simple, one-person job.

For much heavier builds, like a big Salatin-style tractor, you might lean toward skids and a separate dolly. Either way, the goal is smooth, easy mobility.

Now for security. Whatever you do, don't skimp here. A basic hook-and-eye latch is practically an open invitation for predators. You need something more robust. Think in terms of latches that require two distinct actions to open, like a carabiner clip paired with a slide bolt. Make sure you install these on every single access point—the main door, the nesting box lid, and any clean-out hatches.

A hard-earned lesson from veteran builders is that predators are relentless. They will test every inch of a coop, and if there's a weak spot, they will find it. A secure latch isn't a friendly suggestion; it's an absolute must for keeping your flock safe.

Weatherproofing and Protection

Your chicken tractor is going to live outside 24/7, baking in the sun and getting hammered by rain and snow. Protecting the wood is absolutely critical for its longevity, especially if you built the upper structure with untreated pine. A good coat of eco-friendly wood sealer or quality exterior paint will dramatically extend the life of your build.

Be sure to focus your efforts on a few key areas:

The entire frame: Every piece of exposed wood needs a protective coat. No exceptions.

The edges of plywood: These spots soak up water like a sponge and are almost always the first places to show signs of rot.

The interior: Painting the inside of the roosting area does more than just seal the wood. It also makes cleanup far easier and can help deter mites.

This step feels like a bit of extra work upfront, but it’s what keeps your tractor from falling apart after just a season or two. You built it to last, so give it the armor it needs to survive the elements. This same principle drove the evolution of commercial chicken housing, where better materials and design were key to building more durable and effective structures.

Long-Term Maintenance Routines

Just like any other piece of farm equipment, your chicken tractor requires a little routine upkeep to stay in top shape. A simple maintenance schedule doesn't take much time but pays you back with years of reliable service.

Weekly Checks:

Inspect latches and hinges: Give them a quick wiggle. Make sure everything is tight, secure, and working as it should.

Check the hardware cloth: Walk around the tractor and look for any bent, broken, or detached sections that could let a predator sneak in.

Monitor ground contact: When you lock the birds up for the night, check that the frame is sitting flush with the ground to stop anything from digging underneath.

Seasonal Upkeep:

Deep clean: At least twice a year, give the whole tractor a thorough scrubbing. Shovel out all the old bedding, scrape the roosts clean, and wash down the interior surfaces.

Re-apply sealer: Before the weather turns, inspect the wood for wear and tear. Touch up the paint or sealer wherever it's needed, paying special attention to areas that get the most exposure.

Tighten all hardware: Daily moves can cause screws and bolts to loosen over time. Do a quick pass and tighten up anything that feels loose.

Sticking to a simple schedule like this ensures your tractor remains a safe, solid, and effective home for your chickens, season after season.

Common Questions About Chicken Tractors

Once you’ve put the finishing touches on your new chicken tractor, the real-world questions start to pop up. It’s one thing to build it, but another to live with it day in and day out. Let’s tackle some of the most common things I hear from folks just getting started. Getting these answers straight will help you use your new build with total confidence.

How Often Should I Move My Chicken Tractor?

This is the big one. For most flocks, moving the tractor every one to three days is the sweet spot. You're aiming for a delicate balance: giving your chickens fresh forage without letting them turn the ground into a barren, muddy mess. Think of it as fertilization, not demolition.

A good visual cue is your best friend here. Just look at the ground. If it’s looking trampled, picked clean, and manure is starting to pile up, it’s past time to roll it to a fresh patch of grass.

For bigger flocks or, especially, for hungry meat birds, a daily move is pretty much non-negotiable. Their appetites are just that intense.

What Is the Best Size for a Chicken Tractor?

The right size really just comes down to your flock. I've found a good rule of thumb is to plan for at least 1.5 to 2 square feet per broiler (meat bird) and 3 to 4 square feet per laying hen. When in doubt, go bigger. A little extra elbow room goes a long way in reducing stress and keeping things clean.

For a typical backyard flock of 4-6 laying hens, a 4x8 foot tractor is a fantastic and manageable starting point. It gives them plenty of room to scratch and roam without being so heavy that a single person dreads moving it.

Remember, the whole point of a tractor is mobility. It’s a safe, mobile home that gives your flock access to fresh pasture. If you build it so big and heavy that moving it becomes a major chore, it completely defeats its own purpose.

How Do I Make My Tractor Predator-Proof?

Predator-proofing is absolutely not the place to cut corners. Your number one defense is 1/2-inch hardware cloth, not chicken wire. A raccoon can peel back chicken wire like it’s nothing and can easily reach right through the wider holes.

Use heavy-duty staples to attach the hardware cloth to the frame, or even better, use screws with washers. It creates a nearly unbreakable barrier.

Secure the Base: Make sure the frame sits flat on the ground every single night. This is your best defense against predators trying to dig underneath.

Use Two-Step Latches: This is critical. A simple hook-and-eye latch is a fun puzzle for a raccoon, not a security measure. Use latches that require two distinct actions to open.

Can I Use a Chicken Tractor in Winter?

You absolutely can, but it takes a few key modifications to keep your flock safe and comfortable when the temperatures drop.

In colder climates, you can wrap three sides of the tractor with a heavy tarp or clear greenhouse plastic. This creates a windbreak that blocks the worst of the weather while still letting in sunlight to warm things up.

Always leave one side—usually the one facing away from the prevailing wind—partially open for ventilation. Good airflow is just as crucial in winter to prevent moisture buildup, which can lead to frostbite on combs and wattles. You'll also want a deep layer of straw or pine shavings on the ground for insulation and a heated waterer to guarantee they always have access to drinkable water. Making these small adjustments is a huge part of successful backyard homesteading through all four seasons.

At The Grounded Homestead, we're dedicated to helping you build a more self-sufficient life, one project at a time. Explore our resources to find the knowledge you need for your homesteading journey at https://thegroundedhomestead.com.

Facebook

Instagram

X

Youtube